Cabinet Scrapers Exposed!

The buzz about scrapers…

Lately, talk of the cabinet scraper and the frustration that this little tool inflicts on a character has created some buzz in the LJ community. This simple, inexpensive, and very effective tool also frustrates me, but for a different reason. I see many people missing out on the joy of using this tool because they are fed too much information that clouds the simple truth.

On the other hand…

On one hand I appreciate the histories and detailed accounts of filing, honing, burnishing, and turning the burr. On the other hand, the cabinet or card scraper is made overly complicated.

When I share my method of sharpening a cabinet scraper with other woodworkers, I am most often discounted and pooh-poohed. It's near heresy because it is not mystical and complicated enough. It does not support the shroud of mystery around some lost art of the craftsman which elevates him to the level of mythical proportions.

Pulling down the shroud of mystery…

There is always more than one way to perform tasks in the shop, but here is how I sharpen my scrapers. This post may look long but it is more photos than text.

Here is a look at the collection of scrapers that I use almost everyday that I work in the shop. I use them quite often in my remodeling as well.

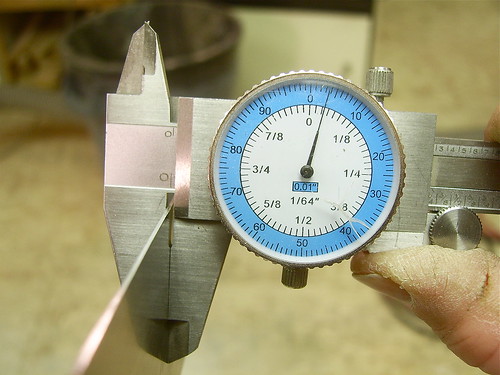

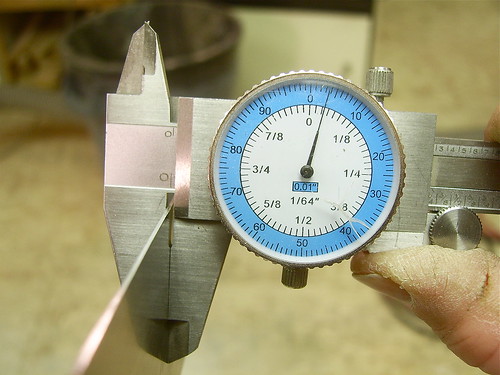

I have no preference of any of them. They are different sizes but they are all basically the same thickness, about 1/32" thick.

There is one card that is thinner which gets used the least. I have enough control of the thick scrapers to perform some of the finest work on veneer and inlays. Here I display the difference in the thickness of the scrapers.

Workflow and sharpening…

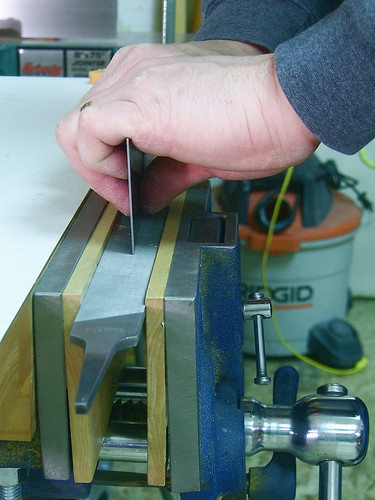

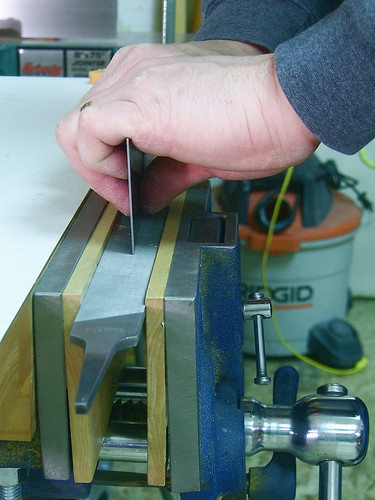

When I am working at the bench and need to use my scrapers, I leave my mill file clamped in the bench vise just like this.

I will scrape my project on one bench and then turn around to the other bench to stroke the card a few times to whip it back into shape. I do not use a jig, I simply hold it by hand at a 90 degree angle on the file. To sharpen I stroke it the full length of the file 3 to 4 times, that is all that is needed. Then I flip it and do the other side. This is exactly how I hold it.

Here is a tip…

One thing I find important is keeping the file clean from the file shavings. I keep compressed air handy to blow off the file. You can feel if the shavings roll under the scraper, this is a sign that it needs to be blown off.

What's your angle?

The easiest way to find the working angle is to hold the card at 45 degrees to the surface. Then stand it back up toward vertical a little more, no more than 1/4 to 1/3 the distance. I don't get hung up on the angle in degrees, it is really by feel. You will get the feel of it as you vary the angle and pressure until it starts to produce fine shavings.

Place your thumbs in the center towards the bottom of the scraper. You can use different areas of the cutting edge by moving the location of your thumbs, thereby applying pressure where you want. You may also pull the scraper applying pressure to the back with your fingers.

This is basically what it will look like.

Here is another view showing some real cabinet scraper action on a piece of reclaimed doug fir flooring.

Here is the flooring with a good bit of scraping done. This piece of wood flooring had a finish on it and sheetrock mud from a remodel project. The cabinet scraper was sharp enough to cut through all of this and make some of the finest shavings.

Here is the result of my sharpening method on a piece of curly maple. This is a difficult piece of wood to plane by hand or machine, but look at the finish and the fine curly shavings.

The next photo shows the scraper results on a piece of Brazilian cherry with a difficult grain pattern. Notice that once again I get consistently fine "angel hair" shavings.

My last photo shows a piece of baltic birch ply that has a maple veneer that I applied. I have total control to scrape the veneer without cutting through it and yet get some nice shavings.

The proof is in the pudding…

Well, there you have it. I sharpen my cabinet scraper with a few strokes on the file and nothing more. I sharpened the scraper between each piece of wood but these are true results for each.

I have no preference as to which cabinet scraper that I use. The cheap Stanley scrapers work just as well as the more expensive Sandvik scrapers.

A balanced point of view…

I will let you know that the cabinet scraper is followed by a random orbital sander in my workflow. I never use the scraper with the intention of the wood surface going straight to finish.

This level of sharpening is very easy to master and then you may find yourself wanting to precede to the next level. I am very satisfied with the performance of my scraper at this level and do not desire to go any further. If you look at my portfolio you can be sure that the cabinet scraper was used in every project and the results speak for themselves so I can stand by my method.

May the shroud of mystery be pulled back and the great Oz be exposed…it is that simple.

Peace, Love, and Woodworking

The buzz about scrapers…

Lately, talk of the cabinet scraper and the frustration that this little tool inflicts on a character has created some buzz in the LJ community. This simple, inexpensive, and very effective tool also frustrates me, but for a different reason. I see many people missing out on the joy of using this tool because they are fed too much information that clouds the simple truth.

On the other hand…

On one hand I appreciate the histories and detailed accounts of filing, honing, burnishing, and turning the burr. On the other hand, the cabinet or card scraper is made overly complicated.

When I share my method of sharpening a cabinet scraper with other woodworkers, I am most often discounted and pooh-poohed. It's near heresy because it is not mystical and complicated enough. It does not support the shroud of mystery around some lost art of the craftsman which elevates him to the level of mythical proportions.

Pulling down the shroud of mystery…

There is always more than one way to perform tasks in the shop, but here is how I sharpen my scrapers. This post may look long but it is more photos than text.

Here is a look at the collection of scrapers that I use almost everyday that I work in the shop. I use them quite often in my remodeling as well.

I have no preference of any of them. They are different sizes but they are all basically the same thickness, about 1/32" thick.

There is one card that is thinner which gets used the least. I have enough control of the thick scrapers to perform some of the finest work on veneer and inlays. Here I display the difference in the thickness of the scrapers.

Workflow and sharpening…

When I am working at the bench and need to use my scrapers, I leave my mill file clamped in the bench vise just like this.

I will scrape my project on one bench and then turn around to the other bench to stroke the card a few times to whip it back into shape. I do not use a jig, I simply hold it by hand at a 90 degree angle on the file. To sharpen I stroke it the full length of the file 3 to 4 times, that is all that is needed. Then I flip it and do the other side. This is exactly how I hold it.

Here is a tip…

One thing I find important is keeping the file clean from the file shavings. I keep compressed air handy to blow off the file. You can feel if the shavings roll under the scraper, this is a sign that it needs to be blown off.

What's your angle?

The easiest way to find the working angle is to hold the card at 45 degrees to the surface. Then stand it back up toward vertical a little more, no more than 1/4 to 1/3 the distance. I don't get hung up on the angle in degrees, it is really by feel. You will get the feel of it as you vary the angle and pressure until it starts to produce fine shavings.

Place your thumbs in the center towards the bottom of the scraper. You can use different areas of the cutting edge by moving the location of your thumbs, thereby applying pressure where you want. You may also pull the scraper applying pressure to the back with your fingers.

This is basically what it will look like.

Here is another view showing some real cabinet scraper action on a piece of reclaimed doug fir flooring.

Here is the flooring with a good bit of scraping done. This piece of wood flooring had a finish on it and sheetrock mud from a remodel project. The cabinet scraper was sharp enough to cut through all of this and make some of the finest shavings.

Here is the result of my sharpening method on a piece of curly maple. This is a difficult piece of wood to plane by hand or machine, but look at the finish and the fine curly shavings.

The next photo shows the scraper results on a piece of Brazilian cherry with a difficult grain pattern. Notice that once again I get consistently fine "angel hair" shavings.

My last photo shows a piece of baltic birch ply that has a maple veneer that I applied. I have total control to scrape the veneer without cutting through it and yet get some nice shavings.

The proof is in the pudding…

Well, there you have it. I sharpen my cabinet scraper with a few strokes on the file and nothing more. I sharpened the scraper between each piece of wood but these are true results for each.

I have no preference as to which cabinet scraper that I use. The cheap Stanley scrapers work just as well as the more expensive Sandvik scrapers.

A balanced point of view…

I will let you know that the cabinet scraper is followed by a random orbital sander in my workflow. I never use the scraper with the intention of the wood surface going straight to finish.

This level of sharpening is very easy to master and then you may find yourself wanting to precede to the next level. I am very satisfied with the performance of my scraper at this level and do not desire to go any further. If you look at my portfolio you can be sure that the cabinet scraper was used in every project and the results speak for themselves so I can stand by my method.

May the shroud of mystery be pulled back and the great Oz be exposed…it is that simple.

Peace, Love, and Woodworking