What to do, what to do

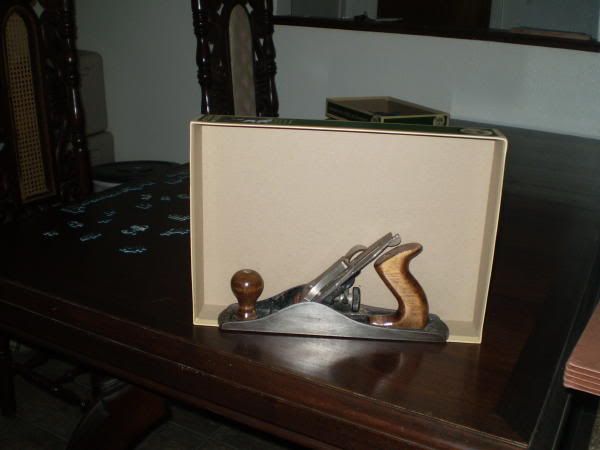

OK you guys know by now that I am having to limit my woodworking to small hand tool stuff, if that. That's going to drive me nuts! I've thought that I would start doing some of my needle work with the idea of incorporating them into boxes, or other woodworking projects in the future when I'm feeling better. Tonight, being Friday, I thought it would be as good time as any to bring out the thread and material and get started. Then….. I went past my little bedroom shop and realized this is going to be harder than I thought. I can't just close the door because that's the bedroom with the cats' favorite "peering out on the world" window. I think the cats own more of this house than the bank does, and certainly more than I do!

I'm not sure exactly what I am going to do. But I thought I'd start this little blog to keep at least my head into the woodworking world. I thought I would just put some general musings and thoughts and maybe some good tips or two that I find along the way of web surfing.

So while I may get the thread and needle moving I'm planning to pepper you with stuff that I learn by reading books and surfing the net. Perhaps I can help with that one tip that makes your project go a little easier. Nothing earth shattering I'm sure, but it will keep me in the woodworking universe. So get ready Lumberjocks--

OK you guys know by now that I am having to limit my woodworking to small hand tool stuff, if that. That's going to drive me nuts! I've thought that I would start doing some of my needle work with the idea of incorporating them into boxes, or other woodworking projects in the future when I'm feeling better. Tonight, being Friday, I thought it would be as good time as any to bring out the thread and material and get started. Then….. I went past my little bedroom shop and realized this is going to be harder than I thought. I can't just close the door because that's the bedroom with the cats' favorite "peering out on the world" window. I think the cats own more of this house than the bank does, and certainly more than I do!

I'm not sure exactly what I am going to do. But I thought I'd start this little blog to keep at least my head into the woodworking world. I thought I would just put some general musings and thoughts and maybe some good tips or two that I find along the way of web surfing.

So while I may get the thread and needle moving I'm planning to pepper you with stuff that I learn by reading books and surfing the net. Perhaps I can help with that one tip that makes your project go a little easier. Nothing earth shattering I'm sure, but it will keep me in the woodworking universe. So get ready Lumberjocks--