I am trying to connect with someone who has experience with both Shaper Origin and fixed CNC of roughly the same price point of $2500. I am trying to decide which direction to go-need to talk to someone who is actually using these machines. I am not a commercial shop. Thanks for reading!

CNC vs Shaper Origin

OLCHIEF

Discussion starter

35 posts

·

Joined 2020

- Add to quote Only show this user

I am trying to connect with someone who has experience with both Shaper Origin and fixed CNC of roughly the same price point of $2500. I am trying to decide which direction to go-need to talk to someone who is actually using these machines. I am not a commercial shop. Thanks for reading!

7,023 posts

·

Joined 2011

RICH has a post about Shaper Origin. Look here, or PM him and ask away.

https://www.lumberjocks.com/topics/311241

https://www.lumberjocks.com/topics/311241

1,531 posts

·

Joined 2008

A Shaper Origin is great for things like mortises and tenons (if you have the table or make one), for large surfaces, for sign making, inlays, etc. It has a "Z" axis but it's really not 3-dimensional (I can't think of the right term), in other words it can make step cut when you define the layers both horizontally but don't plan on doing carvings with it because it can only cut one horizontal layer at a time. A CNC is great for carving type items that have a lot of features, layers, and fine detail. The biggest downside is the bed size for many of the affordable sizes, and the space needed for the larger bed size. A CNC can do almost everything the Origin can as long as it fits within the confines of the bed, but a Shaper Origin cannot do everything that a CNC can do.

Disclaimer: I don't own either. I have researched the heck out of them because I would like to purchase on or the other. I responded because I don't have a pony in the race so I'm not going to try to convince you why one is better than the other.

Disclaimer: I don't own either. I have researched the heck out of them because I would like to purchase on or the other. I responded because I don't have a pony in the race so I'm not going to try to convince you why one is better than the other.

11,344 posts

·

Joined 2014

The real question you have to answer is what you want to do with it. In the $2500 range, a stationary CNC is not going to be very large so you will be more limited to how large of a project you will be able to do with it. I don't have the Shaper Origin but my understanding is that it is strictly a 2D device which means that it can cut things out and it can handle some joinery with the right setup. It can handle inlay's for example by cutting pockets and the inlay pieces. There are some impressive videos on YouTube that demonstrate the inlay process. Most CNC machines can handle 3D relief carving and true V-carving with the right software. The SO may be able to handle some basic signs using a V-bit but I don't think that it can do a true V-carve that requires changing the depth of cut dynamically. I've never seen that demonstrated with the SO anyway.

Another interesting entry into the mix (coming soon?) is the Goliath CNC. It looks like it is basically an autonomous Shaper Origin or robot CNC.

Another interesting entry into the mix (coming soon?) is the Goliath CNC. It looks like it is basically an autonomous Shaper Origin or robot CNC.

8,398 posts

·

Joined 2016

Since the usual LumberJock speculation is going on here, I'll just say that no one can tell you which is better because they are different, and it depends on your intended use.

My good buddy woodbutcherbynight posted the link to my thread in post #1 here, which also includes a link to a blog series I'm working on. A blog post on the Shaper Workstation is coming soon, as is much more I'm doing with it to create fixtures for the Festool MFT, and any other 20mm dog hole table system. I'm even working on a 24×48 inch top for the Bora Centipede that will have the MFT dog hole arrangement for use at the job site. Combine that with a track saw and parf dogs, and it's a precision cutting system for the road.

Disclaimer: I am a local representative for the sales of Shaper Tools, doing demonstrations and developing classes to teach the many features of the Origin and Workstation.

My good buddy woodbutcherbynight posted the link to my thread in post #1 here, which also includes a link to a blog series I'm working on. A blog post on the Shaper Workstation is coming soon, as is much more I'm doing with it to create fixtures for the Festool MFT, and any other 20mm dog hole table system. I'm even working on a 24×48 inch top for the Bora Centipede that will have the MFT dog hole arrangement for use at the job site. Combine that with a track saw and parf dogs, and it's a precision cutting system for the road.

Disclaimer: I am a local representative for the sales of Shaper Tools, doing demonstrations and developing classes to teach the many features of the Origin and Workstation.

11,344 posts

·

Joined 2014

Feel free to correct any incorrect "speculation" that's been provided.

8,398 posts

·

Joined 2016

Did I mention you specifically, Nathan? I wasn't aware you owned the Origin.Feel free to correct any incorrect "speculation" that s been provided.

- Lazyman

8,398 posts

·

Joined 2016

I should clarify-I don't work for Shaper Tools. Rather, I support the sales and promotion of their products locally.Disclaimer: I am a local representative for the sales of Shaper Tools

- Rich

11,344 posts

·

Joined 2014

You didn't really say anything that was on topic, Rich, Just wondering why you stopped by to criticize if your weren't going to add any info or at least correct anything that you think is misinformation.

I said I didn't own one but I did research it and briefly tried one at a demo before buying a CNC. There probably aren't too many people who have both so I added what I learned that might be relevant.

I said I didn't own one but I did research it and briefly tried one at a demo before buying a CNC. There probably aren't too many people who have both so I added what I learned that might be relevant.

8,398 posts

·

Joined 2016

Not on topic? I couldn't have been more on topic, nor did I say anything about misinformation. That's your word choice, not mine. Show me where I criticized anything or anyone.You didn't really say anything that was on topic, Rich, Just wondering why you stopped by to criticize if your weren't going to add any info or at least correct anything that you think is misinformation.

- Lazyman

I have the Shaper Origin and have spent in the hundreds of hours using it, both with the online solutions available on the Shaper Hub, and with my own designs I've created with my vector software.

I added information by pointing out that woodbutcherbynight shared a link to my thread, which also contains a link to my blog series on the tools. I guess you missed that part.

Check them out if you want to learn more about the tool. It's pretty informative, and I cover many details on the "topic."

Since you own a CNC, maybe you should start your own series on using one. I won't be able to comment on it since you have me blocked, just as you won't be able to comment on mine.

8,398 posts

·

Joined 2016

Back to the OP, OLCHIEF. Sorry the choice was made to turn this into a personal attack on me since that isn't helpful to you. There are many here who can offer their experience if we know more about your needs.

What sort of projects do you need or want one of the tools for? That will help steer the answers in the right direction. No one choice is the best for every situation. The links posted above will give you much more information about the Shaper Origin, but I'll be happy to share with you here what I've learned using it.

And, as woodbutcherbynight said, feel free to send me a personal message with your particular needs if you care to. I'll be happy to help in any way I can.

What sort of projects do you need or want one of the tools for? That will help steer the answers in the right direction. No one choice is the best for every situation. The links posted above will give you much more information about the Shaper Origin, but I'll be happy to share with you here what I've learned using it.

And, as woodbutcherbynight said, feel free to send me a personal message with your particular needs if you care to. I'll be happy to help in any way I can.

OLCHIEF

Discussion starter

35 posts

·

Joined 2020

Thank you all for responding to my question. I know very little about CNC, but want to add the capability. I am a hobbyist with a large shop, not a contractor, and have been impressed with the work I have seen using the technology. But I do not understand how to execute it.

One of my questions, concerning the capability for 3D relief carvings, I believe has been answered. Portability is interesting, but I can only think of a couple applications where that would be something I need, like inlaying on a wood floor, a sign post, etc. I am also interested in knowing the level of difficulty for getting a design into the computer files of the machine. I retired from 42 years in law enforcement, not computer programming. When I read some of the descriptions of these things sometimes the language is so esoteric that my eyes glass over and I want to go take a nap. Are there plug and play designs? Can I scan a design with a scanner and go from there? Do I need a whole other computer program for design, or does that software come with the machine? I want simple, ease of use. Or do I need to get my 12 year old granddaughter to come program things for me?

Rich I will check out your blog.

One of my questions, concerning the capability for 3D relief carvings, I believe has been answered. Portability is interesting, but I can only think of a couple applications where that would be something I need, like inlaying on a wood floor, a sign post, etc. I am also interested in knowing the level of difficulty for getting a design into the computer files of the machine. I retired from 42 years in law enforcement, not computer programming. When I read some of the descriptions of these things sometimes the language is so esoteric that my eyes glass over and I want to go take a nap. Are there plug and play designs? Can I scan a design with a scanner and go from there? Do I need a whole other computer program for design, or does that software come with the machine? I want simple, ease of use. Or do I need to get my 12 year old granddaughter to come program things for me?

Rich I will check out your blog.

11,344 posts

·

Joined 2014

You accused us of speculating, Rich. I guess you've forgotten about that comment, though pretty typical for you to claim to be the victim of your own abuse. My comment was simply asking you to identify anything you thought was not accurate. Your reputation for rudeness and bullying precedes you so it is natural for us to think the worst when you make comments like that. You are probably one of the most knowledgeable guys on LJ but it often gets lost because of the way you come across.

BTW, I have read your forum and blog. Not much there that is on this topic (comparison of standard CNC and SO) or that can't be gotten from their website and you instructed everyone that the forum thread was just about the Shaper Origin and the vibe seem to be to not talk about other types of CNC. About the only discussion in your blog amounted to you insulting KellyCrafts (who has a SO) to the point that he won't contribute anymore to your discussion. Caveat emptor.

BTW, I have read your forum and blog. Not much there that is on this topic (comparison of standard CNC and SO) or that can't be gotten from their website and you instructed everyone that the forum thread was just about the Shaper Origin and the vibe seem to be to not talk about other types of CNC. About the only discussion in your blog amounted to you insulting KellyCrafts (who has a SO) to the point that he won't contribute anymore to your discussion. Caveat emptor.

11,344 posts

·

Joined 2014

OL Chief, The design process is usually what stymies new CNC users. Depending upon which stationary CNC machine you buy and what you want to do with it, the software stack can be a fairly large additional expense and a steep learning curve, especially if you've never used any CAD-like design software. Most of the hobbyist grade machines seem to come with some sort of design software but might not have 3D relief carving design capability. Mine for example came with a license for V-Carve Desktop which handles 2D and V-carving design well but you can only import 3D reliefs if they are in the right format (think 3D clip art). V-Carve can import 3D designs from Sketchup but making it ready for carving can be problematic. I typically just use Sketchup for 2D layouts when I struggle with complex 2D designs in V-Carve, mostly because I am more more familiar with the SU drawing tools. To get the full 3D design capability from V-Carve you have to upgrade to V-Carve Aspire which may cost you over $1k. You typically cannot simply scan an image and have it convert to a ready to mill design but V-Carve and other packages like Sketchup and Fusion 360 can import an image that you can use for tracing or converting into vectors you can use to generate tool paths. I am pretty sure that you can download a trial copy of the various versions of V-Carve. You can follow some of their many tutorials to see if the design process is something that you will want to do or if you would have to outsource to your grand daughter. Their tutorials are actually pretty good.

EDIT: Here is a link to the V-Carve Trial versions.

EDIT: Here is a link to the V-Carve Trial versions.

8,398 posts

·

Joined 2016

I'm glad we're back on track here, OLCHIEF. I don't have hands-on experience with flatbed CNC machines, so I'll leave that to others to comment on.

Yes, doing large signs or inlays on a large piece is definitely a job for the Shaper Origin. Pretty much anything that's too large for the bed of a CNC machine. In that price range, I'm not aware of CNC options that can do large pieces.

Regarding getting the design into the machine, the Origin really only needs vector files that consist of lines and enclosed shapes like, say, a bow tie insert for a table top. The tool itself has CAD capability for simple shapes that is very easy to use, but naturally, since it's simple, it's also not super powerful.

Say you wanted to cut a bow tie insert. The tool knows where it is on the work surface from having scanned it with the tape in place. Its display shows that relative to an origin that you set extremely accurately and in a grid spacing of your choosing. Just like graph paper, you could set that grid to 1" x 1" or something else, larger or smaller So, to get that bow tie shape into it, you could enter its design mode and set the points to whatever dimensions you want to create the shape. Once done, you can use that same bow tie again and again.

You also only need one design to cut both the insert and to cut the area on the work piece for it to fit in. That's done using its ability to cut inside or outside a shape, and that's set with just a couple of presses on its touch screen.

I won't kid you. Designing your own stuff with vector software requires some level of computer literacy. However, since you asked about scanning from paper, yes there are options out there for converting a scan of a drawing on paper into a vector file format that the Shaper can use. You can find web sites where you can upload a scan of your drawing and it will convert it and then you download that result and load it onto the tool. I have a very inexpensive IOS app for my iPad that does just that and works very well.

The Shaper Tools web site has hundreds of files you can download, provided by both users and the staff at Shaper Tools. For example, there are ready made files for different sizes of SOSS hinges, 35mm Euro hinges, etc. There is also a growing community of users sharing their designs on other sites as well.

I'll add the tool's onboard design features and a little bit about converting a scan to my list of blog entries for my series, and when it's ready, I'll post a link to it here in your thread.

Update: I just remembered that there is a free online vector design option called Vectr. I haven't used it, but I know of it because Shaper Tools mentioned it as one of the options for creating designs for the Origin.

Yes, doing large signs or inlays on a large piece is definitely a job for the Shaper Origin. Pretty much anything that's too large for the bed of a CNC machine. In that price range, I'm not aware of CNC options that can do large pieces.

Regarding getting the design into the machine, the Origin really only needs vector files that consist of lines and enclosed shapes like, say, a bow tie insert for a table top. The tool itself has CAD capability for simple shapes that is very easy to use, but naturally, since it's simple, it's also not super powerful.

Say you wanted to cut a bow tie insert. The tool knows where it is on the work surface from having scanned it with the tape in place. Its display shows that relative to an origin that you set extremely accurately and in a grid spacing of your choosing. Just like graph paper, you could set that grid to 1" x 1" or something else, larger or smaller So, to get that bow tie shape into it, you could enter its design mode and set the points to whatever dimensions you want to create the shape. Once done, you can use that same bow tie again and again.

You also only need one design to cut both the insert and to cut the area on the work piece for it to fit in. That's done using its ability to cut inside or outside a shape, and that's set with just a couple of presses on its touch screen.

I won't kid you. Designing your own stuff with vector software requires some level of computer literacy. However, since you asked about scanning from paper, yes there are options out there for converting a scan of a drawing on paper into a vector file format that the Shaper can use. You can find web sites where you can upload a scan of your drawing and it will convert it and then you download that result and load it onto the tool. I have a very inexpensive IOS app for my iPad that does just that and works very well.

The Shaper Tools web site has hundreds of files you can download, provided by both users and the staff at Shaper Tools. For example, there are ready made files for different sizes of SOSS hinges, 35mm Euro hinges, etc. There is also a growing community of users sharing their designs on other sites as well.

I'll add the tool's onboard design features and a little bit about converting a scan to my list of blog entries for my series, and when it's ready, I'll post a link to it here in your thread.

Update: I just remembered that there is a free online vector design option called Vectr. I haven't used it, but I know of it because Shaper Tools mentioned it as one of the options for creating designs for the Origin.

8,398 posts

·

Joined 2016

Good grief, Nathan. Everyone speculates. The mind would be a pretty dull place without it. Look up the word. It does not imply misinformation, nor did I ever use that word.You accused us of speculating, Rich.

- Lazyman

In fact, I'm going to speculate right now that OLCHIEF is pretty tired of you making his thread all about how you dislike me and accusing me of things I never said, nor implied. You have me blocked. Once I saw that last night, I chose to return the favor, so let's just move on. This is not helping anyone.

3,999 posts

·

Joined 2013

Olchief, the only two positives for the SO are portability and storage. The same programs can be used for both options to draw or edit your design. The main downfall which has already been mentioned is the SO won't do ramp cuts. A unmentioned downfall is you have to be there with your hands on it. After I test a file made for my stationary cnc and make sure it is good running file, I can rerun that file anytime without having to be there with it. I can be in the shop working on something else, playing in the yard with the dog, spending time with my daughter or whatever else I feel like doing at the time. I can also if I need something carved out of the shop I can always just make a template on the stationary CNC to use later with my regular router then cut in the sharp points a chisel. If you have the room the stationary CNC is the best option just for the versatility of what I can do with it you can even add a laser to it and now your off on laser cutting or engraving. The SO is a neat idea but at the price there are better options with a wider range of capabilities if you have the space.

I haven't found a program that is a scan and go type thing. You will still need to size it and choose what bit you will be using. On my stationary CNC I can import a picture straight from my labtop then choose the carving dimensions, bit sizes for depth then it will carve that picture. Same steps with the laser minus I would switch the photo to grey scale in a different program as my CNC controller doesn't have that option. You will need two separate progams you will have the CNC controller and program that will convert your object to gcode then that is sent over to the controller. That is the CAD and CAM part of CNC. Also my machine is open ended so as long as the work piece is less then 3' wide I can do any length of a project as long as I do it in 4' lengths. Like a 7' child measuring board I could do as two files. Let it cut the first 4' and then line the next file up at the 4' mark as the new zero mark and keep going.

I haven't found a program that is a scan and go type thing. You will still need to size it and choose what bit you will be using. On my stationary CNC I can import a picture straight from my labtop then choose the carving dimensions, bit sizes for depth then it will carve that picture. Same steps with the laser minus I would switch the photo to grey scale in a different program as my CNC controller doesn't have that option. You will need two separate progams you will have the CNC controller and program that will convert your object to gcode then that is sent over to the controller. That is the CAD and CAM part of CNC. Also my machine is open ended so as long as the work piece is less then 3' wide I can do any length of a project as long as I do it in 4' lengths. Like a 7' child measuring board I could do as two files. Let it cut the first 4' and then line the next file up at the 4' mark as the new zero mark and keep going.

11,344 posts

·

Joined 2014

As I said Rich, your reputation precedes you. Those words from almost anyone else would have a been taken in a totally different context. Plenty of evidence of your sort of context around here, even in your forum and blog links posted above. And as I have said to you before, I don't back down from bullies. I've blocked and unblocked you several times and actually appreciate the reciprocal block as it would be in poor form to accidentally comment on someone's forums or blogs whom you have blocked. Moving on.

193 posts

·

Joined 2010

I think the similarities and differences are like that of a table saw and track saw.

One thing to keep in mind is that the SO is limited to what Origin releases as features. CNC on the other hand are much more open in the sense of controls and what software you can use to control them. If you are tinkerer, the CNC would probably be a better choice.

But what is comes down to is what projects are looking to use these for? With a proficient user I am sure either can produce most projects. In either case there is a lot to learn from the get go. Some of the things to learn are going to the same for both (creating the geometry that you want to carve). Some tasket will be similar but specific to the tool (holding the workpiece, setting of the tool). Other steps are going to be specific to the tool and workflow (setting speeds and feeds in the cnc depend on the bit and material be carved, laying out the tape for the SO, etc)

In either case getting educated on the work flow for each will get a better understanding of how each will fit your needs. My suggestion is to get both.

One thing to keep in mind is that the SO is limited to what Origin releases as features. CNC on the other hand are much more open in the sense of controls and what software you can use to control them. If you are tinkerer, the CNC would probably be a better choice.

But what is comes down to is what projects are looking to use these for? With a proficient user I am sure either can produce most projects. In either case there is a lot to learn from the get go. Some of the things to learn are going to the same for both (creating the geometry that you want to carve). Some tasket will be similar but specific to the tool (holding the workpiece, setting of the tool). Other steps are going to be specific to the tool and workflow (setting speeds and feeds in the cnc depend on the bit and material be carved, laying out the tape for the SO, etc)

In either case getting educated on the work flow for each will get a better understanding of how each will fit your needs. My suggestion is to get both.

8,398 posts

·

Joined 2016

Excellent input from diverlloyd above.

I added a blog entry on using the built-in design tools for the Shaper Origin.

I added a blog entry on using the built-in design tools for the Shaper Origin.

77 posts

·

Joined 2020

If I was making this decision, I would probably pick a stationary CNC for general woodworking.

Note, I have never used the Shaper origin.

A stationary CNC lets you add a rotary axis under it, you can cut nice "turnings" like fancy table legs, a lot of the STL files on Thingiverse, etc.

No need for the "domino tape" with a stationary CNC.

The Shaper Origin needs to use the piece of wood that it's cutting as a "Base" to support itself.

This will limit what you can cut.

Look at the 3 minute mark of this video:

The CNC is cutting a "bowl" with a carving in it.

The shaper origin would struggle with doing a carving like this once a certain size is reached because it would lose material to support itself.

If you get the Shaper Origin, I think you are limited to their software. If you get a regular CNC, you can use the Aspire products, Deskproto, Fusion 360, etc.. A lot more options. Plus there's wizards people have made for Mach (traditional CNC). I have wizards for dovetails (through and half blind), box joints, etc.

The shaper origin could probably cut small parts out of small pieces of wood, but again, you have to support the base, so it's more setup .. Like suppose you want to cut out a bunch of marquetry pieces ..

You can start a job on a traditional CNC and then sweep the workshop or do something else productive as the CNC does the work for you. With the shaper origin, you have to push it around. So if the Origin could do a 3 hour engraving job (I don't know if it can or not), I guess you have to push it around for 3 hours? That's a huge disadvantage.

On a traditional CNC, you can put a much more powerful router/spindle than the shaper origin. Numerous advantages to that.. For example, I can cut 3/4 plywood with a compression bit in one pass. The origin is not going to be able to do that.

In all honestly, if it was my decision, I'd only get the origin if I had to take it to a job site or I was super limited in space and could not put a traditional CNC in my shop.

Note, I have never used the Shaper origin.

A stationary CNC lets you add a rotary axis under it, you can cut nice "turnings" like fancy table legs, a lot of the STL files on Thingiverse, etc.

No need for the "domino tape" with a stationary CNC.

The Shaper Origin needs to use the piece of wood that it's cutting as a "Base" to support itself.

This will limit what you can cut.

Look at the 3 minute mark of this video:

The shaper origin would struggle with doing a carving like this once a certain size is reached because it would lose material to support itself.

If you get the Shaper Origin, I think you are limited to their software. If you get a regular CNC, you can use the Aspire products, Deskproto, Fusion 360, etc.. A lot more options. Plus there's wizards people have made for Mach (traditional CNC). I have wizards for dovetails (through and half blind), box joints, etc.

The shaper origin could probably cut small parts out of small pieces of wood, but again, you have to support the base, so it's more setup .. Like suppose you want to cut out a bunch of marquetry pieces ..

You can start a job on a traditional CNC and then sweep the workshop or do something else productive as the CNC does the work for you. With the shaper origin, you have to push it around. So if the Origin could do a 3 hour engraving job (I don't know if it can or not), I guess you have to push it around for 3 hours? That's a huge disadvantage.

On a traditional CNC, you can put a much more powerful router/spindle than the shaper origin. Numerous advantages to that.. For example, I can cut 3/4 plywood with a compression bit in one pass. The origin is not going to be able to do that.

In all honestly, if it was my decision, I'd only get the origin if I had to take it to a job site or I was super limited in space and could not put a traditional CNC in my shop.

77 posts

·

Joined 2020

Just thought of another example.

I made some custom crown molding on my traditional CNC a few months ago.

Each piece (About 8 feet long) took about 9 hours to cut.

There was only about 1/2 inch at the "top" and "bottom" of the molding when I was done.

This job would have been difficult or impossible with the origin.

I made some custom crown molding on my traditional CNC a few months ago.

Each piece (About 8 feet long) took about 9 hours to cut.

There was only about 1/2 inch at the "top" and "bottom" of the molding when I was done.

This job would have been difficult or impossible with the origin.

8,398 posts

·

Joined 2016

Not true. Any software that can export SVG files can be used to create designs for the Shaper. I have used it to cut dovetails and many other more complex operations.If you get the Shaper Origin, I think you are limited to their software.

- paulLumberJock

7,023 posts

·

Joined 2011

For the OP. Some good advice on each tools strength and weaknesses. Tough call. But either way to use one you will need some advancing of your computer knowledge. That will be helpful for other things not ww related. A bonus as it were. No matter which you try you will experience the oops factor.

Sucks I know. LOL

Sucks I know. LOL

1,811 posts

·

Joined 2019

This is very good to know. I'm not in the market for either at the moment but having years of experience in Adobe Illustrator means no real software learning curve with the Shaper.Not true. Any software that can export SVG files can be used to create designs for the Shaper. I have used it to cut dovetails and many other more complex operations.

- Rich

8,398 posts

·

Joined 2016

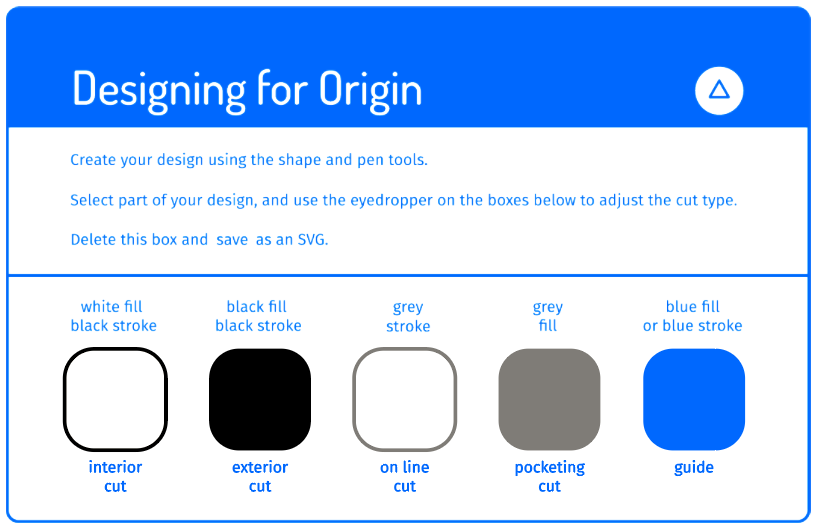

You're all set then. The design files are very simple, just lines and enclosed shapes. The image below shows the different stroke and fill colors to do various types of cuts like inside and outside the lines. You can also just draw the shapes, and choose on line, inside and outside right on the tool when you're cutting. I show some of that in the blog post I linked to in post #19.This is very good to know. I m not in the market for either at the moment but having years of experience in Adobe Illustrator means no real software learning curve with the Shaper.

- sansoo22

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 2.5M

- members

- 128K

- Since

- 2006

A forum community dedicated to professional woodworkers and enthusiasts. Come join the discussion about shop safety, wood, carpentry, lumber, finishing, tools, machinery, woodworking related topics, styles, scales, reviews, accessories, classifieds, and more!

Top Contributors this Month

View All

aboveboard

222 Replies

bandit571

159 Replies

Arthur2sheds

113 Replies