Really. I don't see any real advantage over a good splitter. Except maybe when ripping angles.

Yes it goes up and down with the blade. So?

At times I considered getting and installing one on my Unisaw but now I don't know…

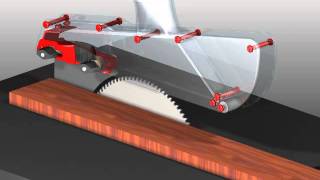

There's been talk about buying a new saw verses old/used to get new safety features like a riving knife. What in a riving knife makes anything safer then a good, in my case, anti-kickback splitter?

Yes it goes up and down with the blade. So?

At times I considered getting and installing one on my Unisaw but now I don't know…

There's been talk about buying a new saw verses old/used to get new safety features like a riving knife. What in a riving knife makes anything safer then a good, in my case, anti-kickback splitter?