Hi Bob

The EU safety regulations are one and they are the same for all the EU countries including UK and Belgium (the site that you pointed is from Belgium). They are translated to 22 languages of the EU countries.

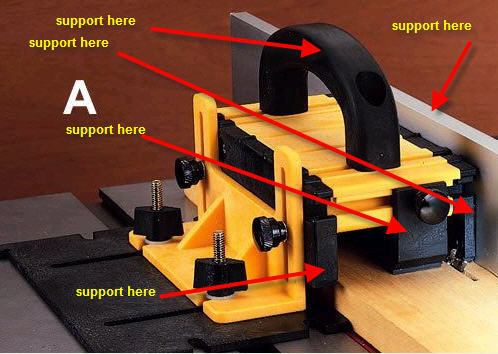

The Gripper is not "banned" in EU because it's not dangerous as a tool…it cannot cause any injury by itself… unless, you through it on somebody

the "ban" is on using any device that requires the removal of the guard on any machine.

Please go to this site and you will see many Q&A of the EU safety comity - Brussels - Belgium (as you can see on page 3)

http://ec.europa.eu/enterprise/mechan_equipment/machinery/facts.pdf

Go to page 113 and you will see that a guard must be installed on all the machines that are "manually loaded" and "manually unloaded".

Also, please have a look on pages 115 , 116

It was just convenient for me to give you the UK safety regulations (the most easy to find) but they are the same regulations as in all the EU (that is very difficult to find).

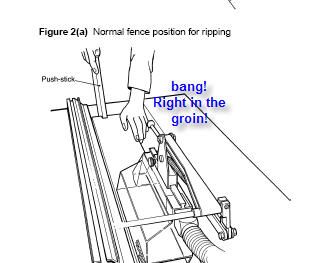

About the picture…it's just a drawing but, we are not afraid to stand behind the part because we have Riving Knife and "Short fence" (by law) for ripping and that combination is satisfactory to prevent kickback….the new table saws in USA are equipped with riving knife but still operated with "long fence" that can cause a kickback and maybe that's the reason that American table saws are equipped also with "anti kickback pawls" that are not required in EU.

About the Griper, if you are visiting WoodNet you could read a few days ago that the handle just broke during operation and the guy had some thoughts about using it…very long post with many "anti" using the Gripper…

By the way, here is what the US OSHA is saing about the guard

http://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=STANDARDS&p_id=9837

1910.213©(1)

Each circular hand-fed ripsaw shall be guarded by a hood which shall completely enclose that portion of the saw above the table and that portion of the saw above the material being cut. The hood and mounting shall be arranged so that the hood will automatically adjust itself to the thickness of and remain in contact with the material being cut but it shall not offer any considerable resistance to insertion of material to saw or to passage of the material being sawed.

So, there is no "ban" on the Gripper but if you'll use it, you are not obeying even the US OSHA safety regulation.

Regards

niki