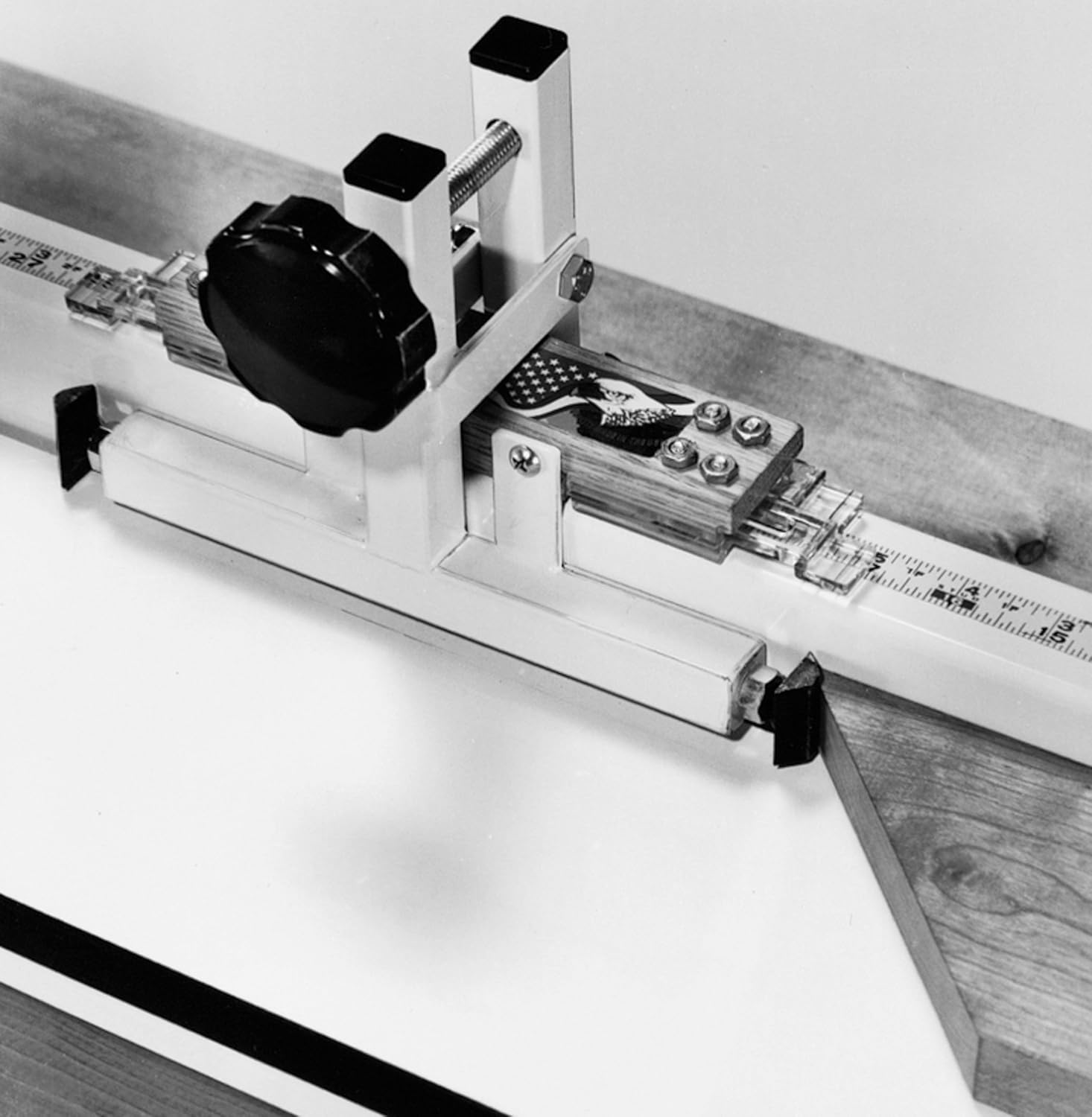

I see people recess their mitre and t track slots on mitre saw stations so they can use them for positioning stop blocks. If I chose a heavy duty combination mini and mitre track could it be useful as a small fence and a stop block track if I decided to not recess it. Any forseen problems ??

I am getting ready to put the plywood top on my mitre saw station and am trying to think it through before completing so I can add any "useful" features. I see people adding fences and I see people saying they are now removing fences in exchange for tracks and stop blocks. So I thought why not keep the combination mitre / mini track above the surface and use it as both a track for stop blocks and the edge for a small fence.

![Image]()

![Image]()

I am getting ready to put the plywood top on my mitre saw station and am trying to think it through before completing so I can add any "useful" features. I see people adding fences and I see people saying they are now removing fences in exchange for tracks and stop blocks. So I thought why not keep the combination mitre / mini track above the surface and use it as both a track for stop blocks and the edge for a small fence.