I want to replace the switch on my 10 inch craftsman table saw and I need some help figuring out the wiring.

![Image]()

In the picture below, the wire from the top is from the motor. It has black, red and white wires.

The wire coming from the bottom is from the plug. It has black, white and green.

Green is the ground and attaches to copper wire and the body of the saw.

White is neutral and is wire nutted to white.

Black from the plug goes into the rocker switch and is then connected to a black box on the right that looks like it has a coil of wire in it. Black and red wires come out and go to the motor. Black and red are both usually hot wires. I'm not sure what that part does.

![Image]()

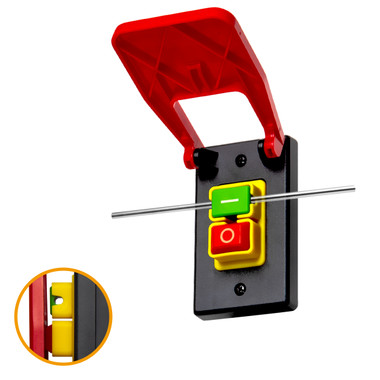

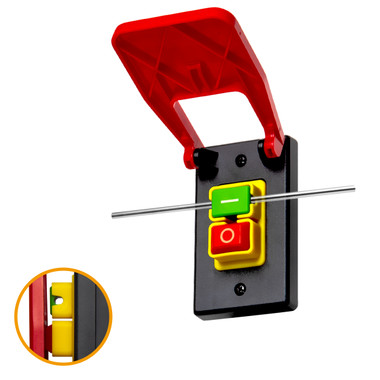

Here's the switch that I bought as a replacement:

![Image]()

powertecproducts.com

powertecproducts.com

It only seems to have one hot that goes to the motor.

I saw this thread:

witch-on-a-craftsman-113-table-saw.21972/#post-36357

Maybe the box with the red and black coming out is a soft start module like in this video?

Thanks for any help you can give me.

In the picture below, the wire from the top is from the motor. It has black, red and white wires.

The wire coming from the bottom is from the plug. It has black, white and green.

Green is the ground and attaches to copper wire and the body of the saw.

White is neutral and is wire nutted to white.

Black from the plug goes into the rocker switch and is then connected to a black box on the right that looks like it has a coil of wire in it. Black and red wires come out and go to the motor. Black and red are both usually hot wires. I'm not sure what that part does.

Here's the switch that I bought as a replacement:

71054 Magnetic Paddle Switch 120V

This Table Saw Safety Paddle Switch provides you with a magnetic emergency stop feature - preventing your tools from powering up after an unexpected outages, blown breakers and other power interruptions

powertecproducts.com

powertecproducts.com

It only seems to have one hot that goes to the motor.

I saw this thread:

witch-on-a-craftsman-113-table-saw.21972/#post-36357

Maybe the box with the red and black coming out is a soft start module like in this video?

Thanks for any help you can give me.