Just built a bed set and used a large timber to make solid 3"x3" legs. Originally had thought of laminating narrower material. Is there a difference in long term stability? At least with solid legs I don't have to worry about which side to face out!

Laminate Legs vs Solid

lobro4

Discussion starter

44 posts

·

Joined 2009

- Add to quote Only show this user

Just built a bed set and used a large timber to make solid 3"x3" legs. Originally had thought of laminating narrower material. Is there a difference in long term stability? At least with solid legs I don't have to worry about which side to face out!

1,581 posts

·

Joined 2009

Actually laminated woods are as strong or stronger then the solid pieces….

For one you can be sure to eliminate any internal checks, knots or other flaws in each segment prior to glue up…whereas a solid piece is hard to see any that do not come through to the suface.

As an example, I have 2 work benches….one with solid 4X4 supports and one that I built using 2 laminated 2×4's. The mass produced shop made (was a bench I inherited) 4×4 has a bad crack going up the side of one support that I have had to glue and clamp. I will someday have to replace this one as the weakness is propelling the crack up the grain which is now into the metal spreader causing it to wobble when the bench clamp is in use for sanding.

The bench I made from laminating has taken a heavy bit of service and the legs and spreaders are not having any problem keeping up and so far no wobbling and no cracking.

That is just one example….I think there are just as many showing on the other side….but I think all in all you will get just as sturdy and item by laminating as you get from solids….and sometimes the smaller dimensional woods are easier to find and cheaper in most cases. Not to mention how easy it is to make the MT joints when the wood is in two pieces….

My .02 cents…

For one you can be sure to eliminate any internal checks, knots or other flaws in each segment prior to glue up…whereas a solid piece is hard to see any that do not come through to the suface.

As an example, I have 2 work benches….one with solid 4X4 supports and one that I built using 2 laminated 2×4's. The mass produced shop made (was a bench I inherited) 4×4 has a bad crack going up the side of one support that I have had to glue and clamp. I will someday have to replace this one as the weakness is propelling the crack up the grain which is now into the metal spreader causing it to wobble when the bench clamp is in use for sanding.

The bench I made from laminating has taken a heavy bit of service and the legs and spreaders are not having any problem keeping up and so far no wobbling and no cracking.

That is just one example….I think there are just as many showing on the other side….but I think all in all you will get just as sturdy and item by laminating as you get from solids….and sometimes the smaller dimensional woods are easier to find and cheaper in most cases. Not to mention how easy it is to make the MT joints when the wood is in two pieces….

My .02 cents…

1,874 posts

·

Joined 2008

on a post the glue lines would just look horrible. but for something like a workbench the laminations would probably add more strength. but the masters before us for many centuries made big massive workbench legs out of solid wood and it worked out fine.

1,501 posts

·

Joined 2008

There's always the quadrilinear method, made popular by the Stickleys. Makes a strong post, just have to get inventive with the top.

334 posts

·

Joined 2008

Teenagewoodworker, I agree with. If the wood is properly selected and dried and all that, then solid legs should do the job just fine… and to be honest, unless the legs are really really, big, where you cannot find the lumber thickness you need or perhaps for design reasons, you really want to make a laminated look or for lack of machines to work thick lumber, then I would go with solid legs.

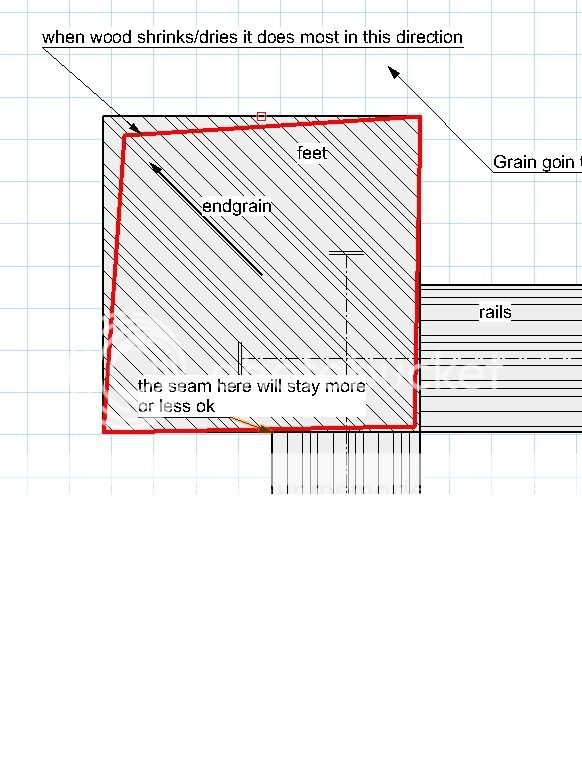

Also the proper way to select solid wood legs is to make sure the grain is going toward the outside of the in a 45°angle from the middle. This to help make sure that the seam between the rails and the feet of the bed or table or bench, does not open up if there is any wood movement.

A picture says a thousand words, Maybe this helps to explain what I am trying to say.

![Image]()

when proper wood grain choice is affected by wood movement:

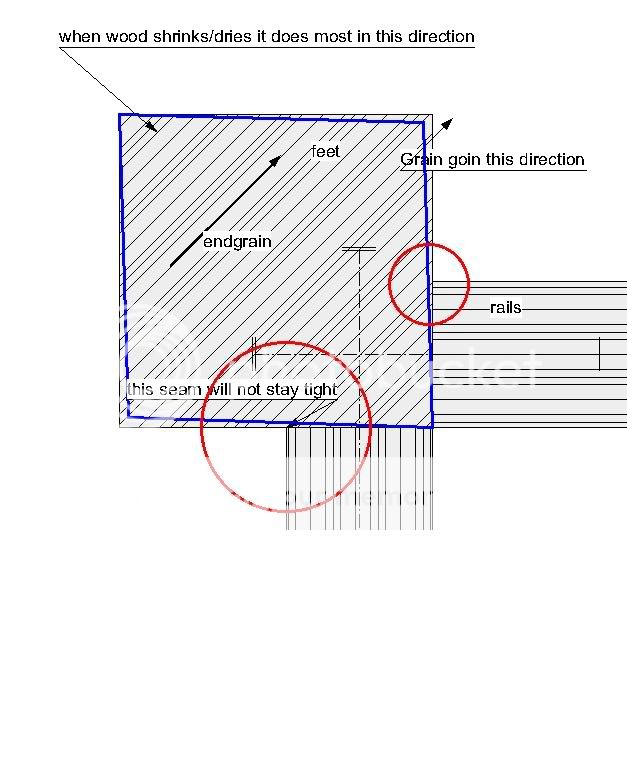

![Image]()

when woodmovement affects such a corner with not so ideal grain choice:

![Image]()

so I hope this illustrates why you should watch which side faces outward as well that you can use solid legs with out a problem…. it just looks better

Also the proper way to select solid wood legs is to make sure the grain is going toward the outside of the in a 45°angle from the middle. This to help make sure that the seam between the rails and the feet of the bed or table or bench, does not open up if there is any wood movement.

A picture says a thousand words, Maybe this helps to explain what I am trying to say.

when proper wood grain choice is affected by wood movement:

when woodmovement affects such a corner with not so ideal grain choice:

so I hope this illustrates why you should watch which side faces outward as well that you can use solid legs with out a problem…. it just looks better

1,624 posts

·

Joined 2008

Hey teen…........... we laminate posts all the time and turn them, paint them, stain them, etc. and we don't have any problems with glue lines. If glued up and clamped properly, you won't see much of if any glueline. And yes, they are stronger and more stable.

334 posts

·

Joined 2008

Good point, it can be that the legs are some what more resistant to movement, but, if you have nice straight grain it should not play a large role for legs on a bed/bench or table.

I am of the opinion that the solid simply looks better. Sure you can have perfect glue lines (invisible) but still the grain has to be perfectly matched, which also uses sometimes more wood, than if one just used a good piece of solid material, up to a point, of course. I think this because if you have stips of wood in a leg, it can look like it was made with "scraps" or you ran out of wood or something… maybe even look like it was made by mass production. Just my opinion, thats all , Just for looks.

I am of the opinion that the solid simply looks better. Sure you can have perfect glue lines (invisible) but still the grain has to be perfectly matched, which also uses sometimes more wood, than if one just used a good piece of solid material, up to a point, of course. I think this because if you have stips of wood in a leg, it can look like it was made with "scraps" or you ran out of wood or something… maybe even look like it was made by mass production. Just my opinion, thats all , Just for looks.

1,163 posts

·

Joined 2008

I use resin glues for laminating if I don't want the glue line showing. Yellow glues are flexible and can show the glue lines with expansion and contraction. Titebond II also works well.

11 posts

·

Joined 2012

This is the problem i am having. Getting ready to build a library stand for my wife and the plans call for 1 3/4 inch square legs. finding 8/4 oak is not exactly cheap and to only get just enough for the legs is hard, so do i laminate 2 one inch boards which is cheaper for go with solid. Ive tried the Stickley way before and it is not as easy as it sounds.

6,000 posts

·

Joined 2010

Paul,

Yes, I would do just that. Laminate three (3) dimensional piece of oak together and plane down to size. Remember that your "one inch" boards are actually going to be 3/4" or maybe even less. If you are feeling creative, you can even pre-thin each of the boards so that your final laminated piece will show three equal thickness pieces in the lamination.

Yes, I would do just that. Laminate three (3) dimensional piece of oak together and plane down to size. Remember that your "one inch" boards are actually going to be 3/4" or maybe even less. If you are feeling creative, you can even pre-thin each of the boards so that your final laminated piece will show three equal thickness pieces in the lamination.

11 posts

·

Joined 2012

well I am starting from rough 5/4 lumber, would you still do three equal pieces or just two and use a veneer to cover the joints?

6,000 posts

·

Joined 2010

I am thinking that if you book match the two pieces and fold one back to the other, the side grains will match and no veneer would be needed nor desired.

2,199 posts

·

Joined 2010

I see this is an old post, but what the hell…

One reason to laminate posts is to prevent 'diamonding' as mentioned above. Another is cost. Take 4×4 oak, the cost of a 16' length the last time I enquired was around €190 + Vat which puts it at over €100 per cubic foot.

If I buy 4/4 oak it works out at around €46 per cubic foot.

The cost goes up per cubic foot as the thickness increases with oak.

Curiously, this does not happen with sapele or pine, but it does for walnut, maple, cherry.

I have never had any problems with PVA glue, usually applied with a small paint roller on both surfaces to get a thin, even covering.

One reason to laminate posts is to prevent 'diamonding' as mentioned above. Another is cost. Take 4×4 oak, the cost of a 16' length the last time I enquired was around €190 + Vat which puts it at over €100 per cubic foot.

If I buy 4/4 oak it works out at around €46 per cubic foot.

The cost goes up per cubic foot as the thickness increases with oak.

Curiously, this does not happen with sapele or pine, but it does for walnut, maple, cherry.

I have never had any problems with PVA glue, usually applied with a small paint roller on both surfaces to get a thin, even covering.

11 posts

·

Joined 2012

Horizontal Mike, the bookmatching worked great and actually looks better than if I use 8/4 stock the glue line is almost invisable. thanks dude

26 posts

·

Joined 2012

if you're going for a 3" finished size leg, I'd start with 8/4 stock, at least 6.5" wide.

rip the board in half, joint and plane the faces, then "fold" the board in half along the cut line, i.e. book match the edge grain along where you sawed in half. After it's glue, joint the edge and plane to final dimension. This way you have three good looking faces on the final product, and a decent looking 4th face, it will be acceptable since it's from the same board, good for the inside facing side of a table leg, or furniture piece where it won't be seen that often.

rip the board in half, joint and plane the faces, then "fold" the board in half along the cut line, i.e. book match the edge grain along where you sawed in half. After it's glue, joint the edge and plane to final dimension. This way you have three good looking faces on the final product, and a decent looking 4th face, it will be acceptable since it's from the same board, good for the inside facing side of a table leg, or furniture piece where it won't be seen that often.

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 2.5M

- members

- 128K

- Since

- 2006

A forum community dedicated to professional woodworkers and enthusiasts. Come join the discussion about shop safety, wood, carpentry, lumber, finishing, tools, machinery, woodworking related topics, styles, scales, reviews, accessories, classifieds, and more!

Top Contributors this Month

View All

aboveboard

212 Replies

bandit571

160 Replies

Arthur2sheds

120 Replies